Intelligent well is a well equipped with monitoring equipment and completion components that can be adjusted to optimize production, either automatically or with some operator intervention.

Intelligent Well Systems combine permanent data acquisition, flow management, and systems integration to deliver reliable remote flow control, without costly well intervention.

Economic Drivers behind the Intelligent Well System

• Intelligent wells improve targeting of new wells

• Lower surface infrastructure expenses

• Commingled flow

• Reduction of workovers

• Better understanding leads to increased recovery

• Water Management

To realize this, the following elements are generally required:

• Flow control devices

• Feed-through isolation packers

• Control, communication and power cables

• Down-hole sensors

• Surface data acquisition and control

Many myths exist about intelligent well technology. “They’re too costly to install and operate. They aren’t known for their reliability. They don’t have a track record. Anyone can install them. They are just a fad.” But the facts tell a different story.

"Intelligent" completions

The principal driving force behind intelligent completions is the need to manage today’s highly leveraged designer wells, which challenge the technical capabilities and economic assumptions of conventional, intervention-based production management.

Among key drivers of intelligent well technologies are:

• Fewer, larger (tubulars and production rate) well completions which complement advanced directional drilling capabilities

• Pre-completion of primary, secondary and tertiary pays to exploit multiple reservoirs within the same primary wellbore, favoring commingled production

• Overall increasing sensitivity to unplanned OPEX, driving reliability (availability) requirements

• Early confirmation (by initial development wells) of the reservoir model and depletion plan. Early confirmation / contradiction of preliminary assumptions about reservoir response can provide valuable insights regarding reserves estimation; adequacy/inadequacy of capital infrastructure plans; number, placement and design of subsequent development wells, etc.

Intelligent Well Technology (IWT) encompasses two primary concepts:

• Surveillance in real time – making measurements of downhole flow and/or reservoir conditions. Measurement is achieved by electronics or fiber optics. Measurements commercially available today are pressure, temperature and flow rate. Downhole pressure/temperature has been available since the 1980s.

• Control in real time – the ability to remotely control zones, by on/off control or choking. Real-time production control has been commercially available only since about 1998. Control is achieved by electric, hydraulic or electro-hydraulic actuation of a valve or sleeve.

Conventional (non-intelligent) well designs require intervention via wireline, coiled tubing, or rig to make measurements or alter zone flow. By installing downhole well measurement and control devices connected to the surface (i.e., "intelligent technology"), measurement and control become possible without intervention.

Intelligent Completions is one of keys to Success of intelligent well

Intelligent Completion technology has matured rapidly to become a widely accepted tool in the completion engineer’s “toolkit.” New reservoir and production models predict inflow and outflow characteristics and show how Intelligent Completion Systems can bring added value in applications.

What qualifies a well as an Intelligent Completion?

Intelligent completions use real-time production and injection management systems to place process controls downhole and provide three basic functions:

1. Acquisition of downhole production and/or reservoir data

2. Analysis of data to optimize production

3. Remote control of flow.

What is the business case for using Intelligent Completion Systems?

Intelligent Completion Systems can change flow characteristics while minimizing interventions and their associated cost, risk and production downtime. This ability potentially can add millions of dollars to a well’s net present value (NPV).

Although minimizing intervention is a significant benefit, intelligent well technologies can provide even more value by accelerating cash flow and increasing ultimate recovery.

Intelligent well system (IWS) and intervention avoidance

Operators use intelligent well technologies for three primary reasons:

• To reduce or eliminate intervention costs

• To accelerate production and reserves and improve reservoir management

• To allow for additional recoverable reserves.

<---Inforce Intelligent Well by Baker Hughes

<---Inforce Intelligent Well by Baker Hughes The single most-often-cited reason for running Intelligent Well Systems is intervention avoidance. Intervention to change zone flow will accomplish one or more of the following objectives:

• Bring on production for a non-producing zone

• Reduce or shut off flow of unwanted gas or water

• Shut off a zone permanently.

Intervention carries with it a high cost, including rig cost , workover fluids, completion equipment, etc. In addition there is an opportunity cost that includes lost production for the duration of the intervention. Ancillary risks include environmental and safety issues.

Eliminating or reducing interventions by using IWS has the potential in some areas to add many millions of dollars to well net present value (NPV). Rig and workover costs alone may range from less than $50,000 in low-rate onshore areas to more than $10 million in offshore deepwater environments. Delayed revenue must also be considered. Thirty days of production delayed by a workover at, say, 10,000 bopd and $15 per barrel, is equivalent to $ 4.5 million delayed revenue.

Using IWS not only reduces or eliminates interventions and their associated costs, but also allows operators to implement drainage strategies that yield more reserves or require less time than with conventional completions.

Figure illustrates a smart well outfitted with a variety of surface and subsurface smart sensors and instrumentation for measuring hydrocarbon pressure and temperature and controlling flow rates. A high volume of valuable real time data is generated to provide experts with an in depth understanding of the hydrocarbon reservoir behaviour. (Source: Shell iWell Technology document 2001)

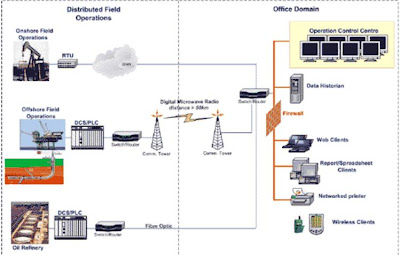

Figure illustrates a smart well outfitted with a variety of surface and subsurface smart sensors and instrumentation for measuring hydrocarbon pressure and temperature and controlling flow rates. A high volume of valuable real time data is generated to provide experts with an in depth understanding of the hydrocarbon reservoir behaviour. (Source: Shell iWell Technology document 2001) Real Time Data Acquisition and Process Control Infrastructure ensures real time process data flow from the sensors and instruments through the telemetry systems (DCS, RTU,PLC) and data communication infrastructure (radio, digital microwave radio, LAN) to the office domain making real time field data available on the users desktop and other visualization tools

Real Time Data Acquisition and Process Control Infrastructure ensures real time process data flow from the sensors and instruments through the telemetry systems (DCS, RTU,PLC) and data communication infrastructure (radio, digital microwave radio, LAN) to the office domain making real time field data available on the users desktop and other visualization toolsReferences:

http://www.spe.org/

http://www.slb.com/

http://www.weatherford.com/

http://www.bakerhughes.com/

No comments:

Post a Comment